MAKING THE PERFECT CRISP

We use a 3 step process in order to consistently achieve crisp perfection in Appearance, Flavour and Texture.

1. Specification: Moisture, thickness, Flavouring, Oil and Size

2. Selection: Potato Variety, Oil type, Flavour portfolio, Packaging

3. Conversion: Slice Selection, Cooking Method and Quality Controls

Preparation and planning are vital, it takes just 14mins from potato to packet and every second 5.5 potatoes are made into handcooked crisps

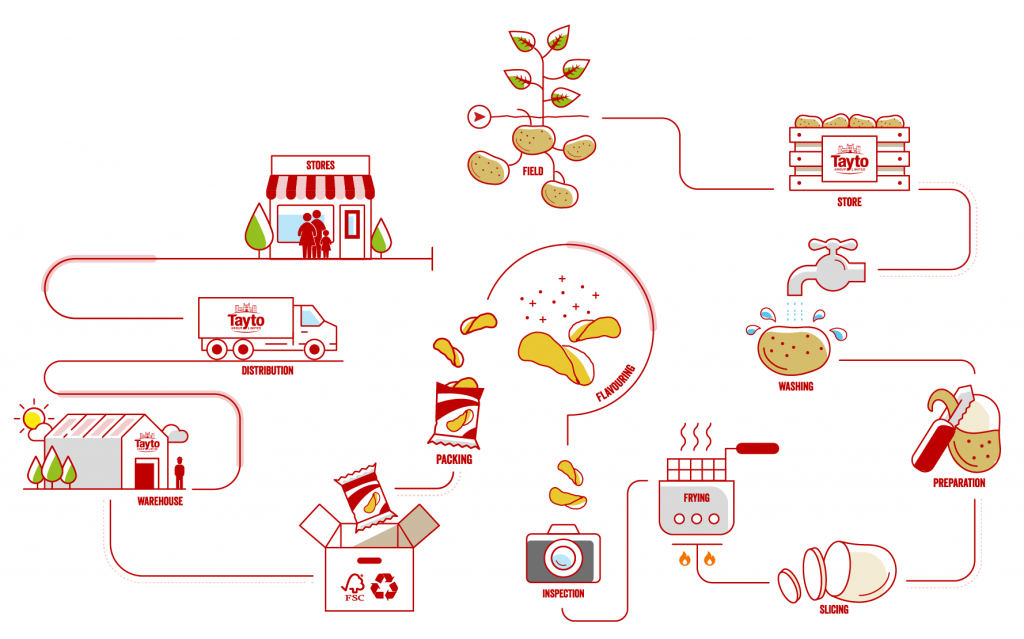

OUR PROCESS

Hand stirring prevents clumping and ensures an even cook. 7 of 13 We only use rapeseed and sunflower oils.

Oil accounts for nearly 1/3 of the finished product.

Fresh oil is added continuously to ensure perfect crisp taste. 8 of 13

Slice thickness is constantly adjusted depending on potato starch and moisture content.

The average potato produces 45 slices.

Our handcooked crisps are 20% thicker than conventional crisps and the starch is left on the sliced potato for a mightier, crispier bite.

Stones and wood are also removed at this stage. 11 of 13 Over sized potatoes are halved and undersized ones are saved for animal feed. 12 of 13

The majority of our potatoes come from the fertile lands of: Lincolnshire, Nottinghamshire, Yorkshire and North East Ireland. All of our GB growers are Red Tractor Assured

13 of 13